2026-01-04

Guide complet de l'excellence préfabriquée : Des maisons extensibles à aile unique aux villas modulaires de luxe (édition 2026)

À une époque définie par une urbanisation rapide et le besoin d'infrastructures durables, la maison modulaire préfabriquée a évolué d'un abri temporaire à une solution de logement sophistiquée et permanente. Ce guide explore l'ingénierie, la polyvalence et les tendances mondiales du marché des maisons de luxe modulaires, des systèmes de containers extensibles et des petites maisons portables.

Conçue avec précision pour redéfinir l'avenir de la construction, une maison modulaire à ossature métallique est fabriquée dans un environnement strictement contrôlé en usine, garantissant que chaque ensemble de maisons modulaires atteint un niveau d'intégrité structurelle bien supérieur à celui des maisons traditionnelles construites sur site. Ce processus avancé utilise des matériaux haute performance, y compris des cadres modulaires en aluminium, des panneaux EPS modulaires et des vitrages modulaires, pour créer des environnements ultra-énergétiques, tandis que la maison modulaire à énergie solaire offre une autonomie hors réseau en intégrant l'énergie renouvelable directement dans l'architecture. Grâce à la polyvalence "semblable à Lego" du design modulaire des maisons conteneurs, ces structures offrent une échelle et une configuration illimitées — allant d'une maison modulaire compacte de 30 mètres carrés à un vaste domaine de maison modulaire de 5 chambres. Finalement, ces maisons modulaires permanentes sont construites pour une durabilité à vie, conçues pour être à la fois résistantes aux ouragans et aux tremblements de terre tout en répondant aux certifications CE rigoureuses et aux normes australiennes.

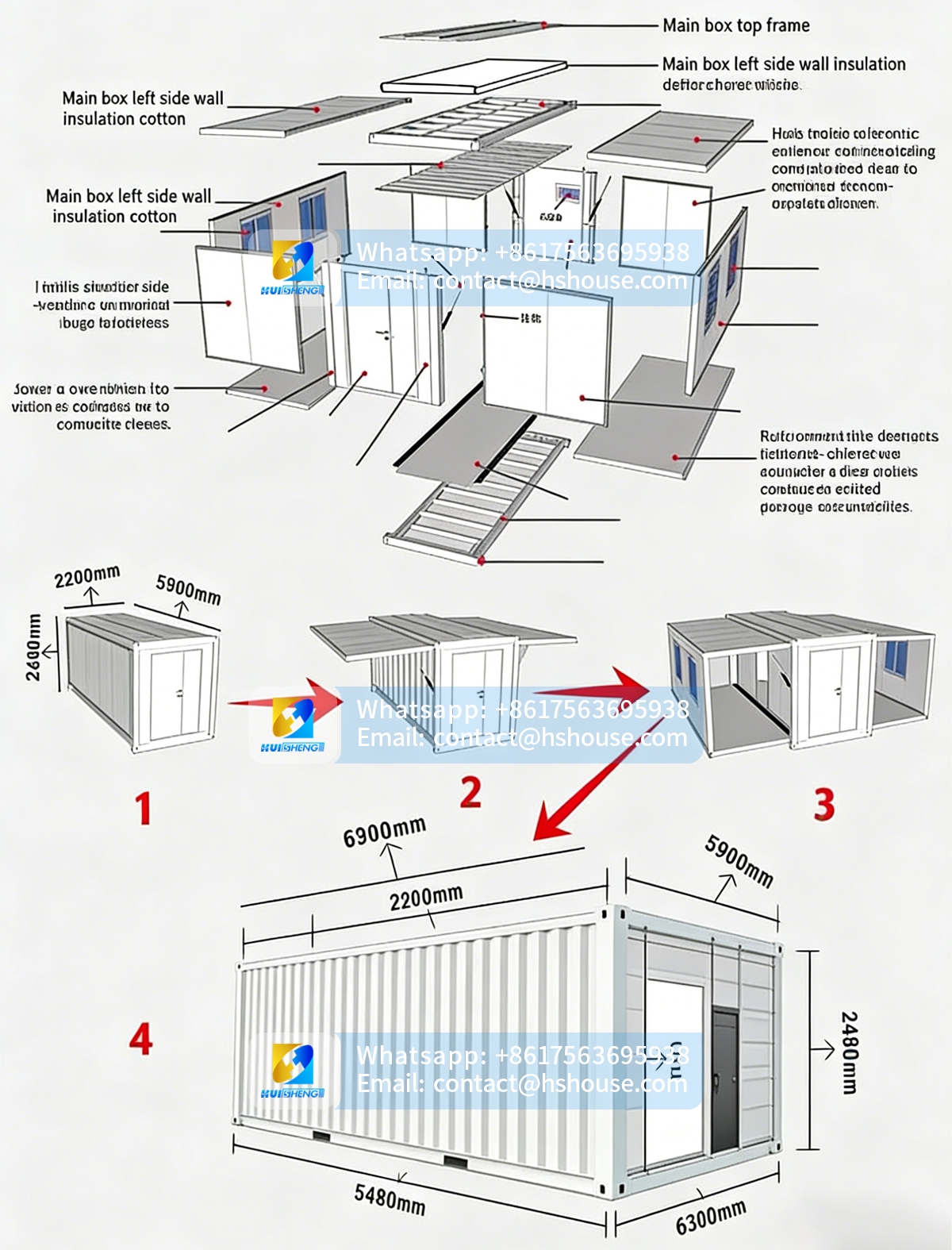

La maison préfabriquée extensible a gagné sa réputation de "couteau suisse" de la construction moderne en résolvant ingénieusement le plus grand obstacle logistique de l'industrie : transporter une résidence spacieuse et volumineuse dans l'empreinte d'un conteneur d'expédition compact.

Pour ceux qui recherchent une expérience plus spacieuse de "manoir dans une boîte", la maison conteneur extensible 40ft représente le sommet du luxe préfabriqué, offrant un espace de vie impressionnant de 75 à 80 mètres carrés dès le déploiement. L'innovation ne s'arrête pas à l'expansion horizontale ; les dernières maisons modulaires préfabriquées à deux étages utilisent un mécanisme sophistiqué à double étage pour offrir une véritable expérience de maison modulaire à deux étages, doublant effectivement la superficie sans augmenter la taille de la fondation. Pour offrir une transition véritablement sans effort "clé en main", des unités premium comme la maison Cammi, maison conteneur extensible, arrivent entièrement meublées et prêtes à l'emploi, avec des salles de bains préfabriquées intégrées, des cuisines de designer et des sols très résistants, garantissant que le confort et le style sont offerts dès que la structure est dépliée.

Le design moderne des maisons modulaires a réussi à briser l'ancien stéréotype de "boîte", ouvrant une nouvelle ère où l'esthétique haut de gamme et l'utilité industrielle coexistent. À l'avant-garde de cette tendance dans le marché du style de vie high-tech se trouve la maison-modulaire-boîte-spatiale, une maison capsule modulaire recouverte d'aluminium qui offre une silhouette aérodynamique et élégante. Ces unités futuristes deviennent de plus en plus la norme pour les hôtels de maisons modulaires et les stations de luxe de glamping, offrant aux invités une expérience premium et technologique que la construction traditionnelle ne peut tout simplement pas reproduire. En combinant des matériaux haute performance avec des lignes architecturales audacieuses, ces capsules offrent une solution "clé en main" pour les promoteurs cherchant à créer des destinations emblématiques et photogéniques sur Instagram en un temps record.

Repoussant encore les limites de l'architecture géométrique, les fabricants proposent désormais des structures emblématiques comme la maison modulaire en dôme et la maison modulaire triangulaire (style A-frame) pour répondre à la demande croissante de propriétés de vacances uniques. Ces maisons modulaires préfabriquées en dôme et kits triangulaires offrent une présence visuelle saisissante qui s'harmonise magnifiquement avec les paysages naturels, en faisant le choix idéal pour les éco-resorts, les cabanes de montagne et les retraites éloignées. Parce que ces unités spécialisées sont construites comme des maisons modulaires prêtes à l'emploi, elles contournent les cauchemars logistiques de la construction en terrain accidenté, permettant aux propriétaires de déployer des chefs-d'œuvre architecturaux dans des endroits auparavant jugés inaccessibles.

Au-delà des usages résidentiels et hôteliers, la modularité est devenue le moyen le plus rapide et le plus rentable de lancer des infrastructures commerciales. La polyvalence de la maison modulaire à ossature métallique permet la création rapide de maisons de café modulaires élégantes, de restaurants préfabriqués éphémères, et même de grands entrepôts en acier préfabriqués. Ces structures offrent aux propriétaires d'entreprises l'agilité nécessaire pour s'adapter ou se déplacer à mesure que les demandes du marché changent. Qu'il s'agisse d'une maison en verre modulaire pour une vitrine de détail ou d'une structure de maison modulaire robuste pour le stockage industriel, le secteur préfabriqué moderne offre une chaîne d'approvisionnement "tout-en-un" qui garantit que les opérations commerciales peuvent commencer en quelques semaines plutôt qu'en quelques années.

Naviguer sur le marché mondial des maisons préfabriquées en Chine nécessite plus que de simplement choisir un design ; cela demande une compréhension approfondie de la ``` conformité régionale et des configurations complexes d'expédition pour garantir une transition fluide de l'usine à la fondation. Les fabricants professionnels ont relevé ce défi en concevant des maisons conteneurs extensibles en gros en Australie qui respectent strictement les normes AS/NZS, ainsi qu'en développant des maisons préfabriquées modulaires à faible coût pour l'Europe qui répondent à toutes les exigences Eurocode et CE nécessaires. En priorisant ces certifications internationales, les fournisseurs garantissent que chaque maison modulaire à ossature métallique est non seulement conçue pour la durabilité, mais aussi "prête à l'emploi" pour divers marchés mondiaux, des régions accidentées de l'outback aux centres urbains denses d'Europe.

Pour répondre aux demandes urgentes de 2026, l'industrie a évolué vers un modèle à fort inventaire de maisons modulaires prêtes à être expédiées, qui sont stockées et prêtes à être envoyées immédiatement. Disponibles dans des tailles standardisées — y compris des configurations de maisons modulaires isolées de 20ft, 30ft et 40ft — ces unités servent de solution de première ligne pour le logement d'urgence, les cliniques médicales de réponse rapide ou les besoins urgents de bureaux préfabriqués. Cette capacité "prête à expédier" garantit que, que vous soyez à la recherche d'une maison modulaire prête à l'emploi pour une ferme privée ou d'une flotte de petites maisons modulaires portables pour un projet gouvernemental, le délai de livraison est réduit de mois à quelques jours, offrant une agilité sans précédent dans le secteur de la construction.

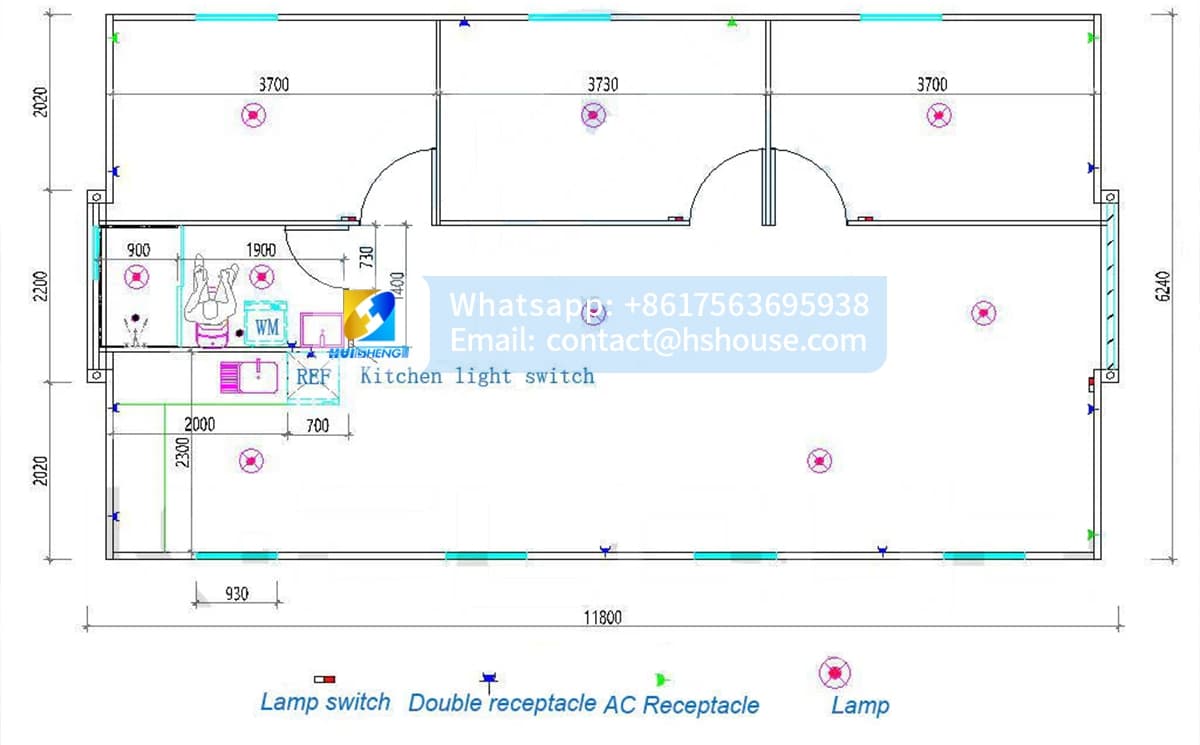

La véritable beauté d'une maison préfabriquée portable réside dans son processus révolutionnaire d'assemblage, souvent résumé par la question : "Comment cela se monte-t-il ?" Contrairement à la nature laborieuse des constructions traditionnelles, une maison conteneur extensible de 20ft peut être entièrement déployée et rendue habitable par une petite équipe en moins de deux heures. Le processus est remarquablement simple, nécessitant seulement une base de structure de maison modulaire de base — comme une dalle de béton ou des piliers nivelés — et des raccordements utilitaires standard pour les systèmes de salle de bain et de cuisine préinstallés. Cette simplicité fait de la maison conteneur modulaire extensible l'atout ultime "clé en main", permettant un logement modulaire permanent de haute qualité avec la vitesse de montage d'un abri temporaire.

Analyse comparative : Modulaire vs. Traditionnel

Caractéristique | Maison Modulaire/Préfabriquée | Construction Traditionnelle |

Temps de Construction | 4 à 8 Semaines (Usine) | 6 à 12 Mois (Sur site) |

Gestion des Déchets | < 5% (Environnement Contrôlé) | ~30% (Déchets sur site) |

Portabilité | Maison modulaire portable à ossature métallique | Fixe |

Prévisibilité | Prix fixe des maisons préfabriquées | Dépassements fréquents du budget |

Conclusion : Investir dans un avenir modulaire

Des maisons préfabriquées les moins chères pour les acheteurs débutants aux maisons modulaires préfabriquées de luxe pour les propriétés de prestige, l'industrie n'est plus un créneau — elle est l'avenir. Avec des innovations comme la maison conteneur extensible de 20ft de large 720mm et les systèmes préfabriqués alimentés par solaire, la vie modulaire offre un chemin résilient, rapide et rentable vers la propriété.

Global housing landscape is witnessing a revolution. As the demand for flexibility, speed, and cost-efficiency grows, foldable houses and mobile modular houses have emerged as the premier solutions for 2026. From the innovative Z-fold house design to luxurious mobile pod houses, these structures are transforming how we...

What Makes Prefabricated Houses the Smarter Choice for Modern Living?A prefabric

How Are Military Mobile Homes and Prefabricated Modular Homes Used in Modern Def

Integrated House: The Future of Prefabricated Modular HomesAn Integrated House i

10ft Double-Wing Expandable Container Home: The Next Generation of Modular Livin

+86 17563695938

+86 17563695938

contact@hshouse.com

contact@hshouse.com

No. 1099, Gongye 1st Street, Weicheng District, Weifang City, Shandong Province, China

No. 1099, Gongye 1st Street, Weicheng District, Weifang City, Shandong Province, China

View on Mobile

Copyright © 2026 Huisheng International Trade All rights reserved

powered by WDL

Send us your requirements. Free custom floor plan or 3D design in 3 working days

Submit form